Water Linked are proud to launch CageSense™ – a wireless sensor system for environmental monitoring in fish farms, following a successful pilot stage at two full scale fish farms during the winter of 2021/22.

Since enticing the aquaculture industry by dropping hints about the concept during the pre-launch at AquaNor 2021, Water Linked have been testing and further developing the wireless sensor system at two full scale fish farms in Central Norway. Bjørn Sirnes, CCO Aquaculture at Water Linked, reports of great results and a product that is ready to hit the market:

– Given the solution has already undergone extensive testing, both over and under water, prior to the pilots, the most suspenseful part was finding out how robust the data gathered in a more hostile environment would be, Sirnes explains.

He further explains that fish farms are hosts to significantly higher levels of interference and acoustic noise compared to other, typically noisy, environments such as docksides where initial product testing was conducted.

– A long-term, robust pilot phase at operational fish farms, accompanied by simultaneous algorithm adaptation was crucial to achieving a product that meets our internal quality standards by delivering robust, accurate data from the sensors, Sirnes says.

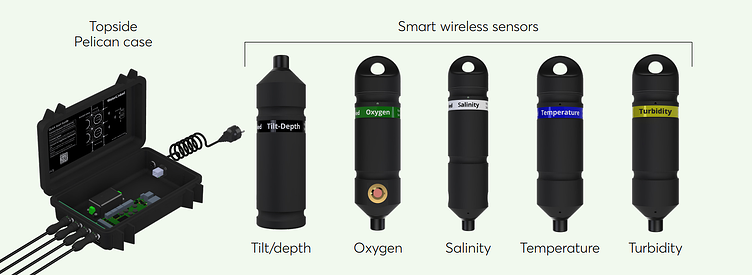

Wireless monitoring of critical environmental parameters

The wireless sensors comprising the CageSense™ system monitor important environmental parameters that affect fish welfare and productivity. All fish farms are legally obliged to monitor some parameters, such as oxygen and temperature. In addition, the CageSense™ sensors measure turbidity and salinity. A fifth sensor, measuring mechanical parameters such as depth and tilt, can be used to monitor how subsea parts of the cage are affected by rough weather and strong current.

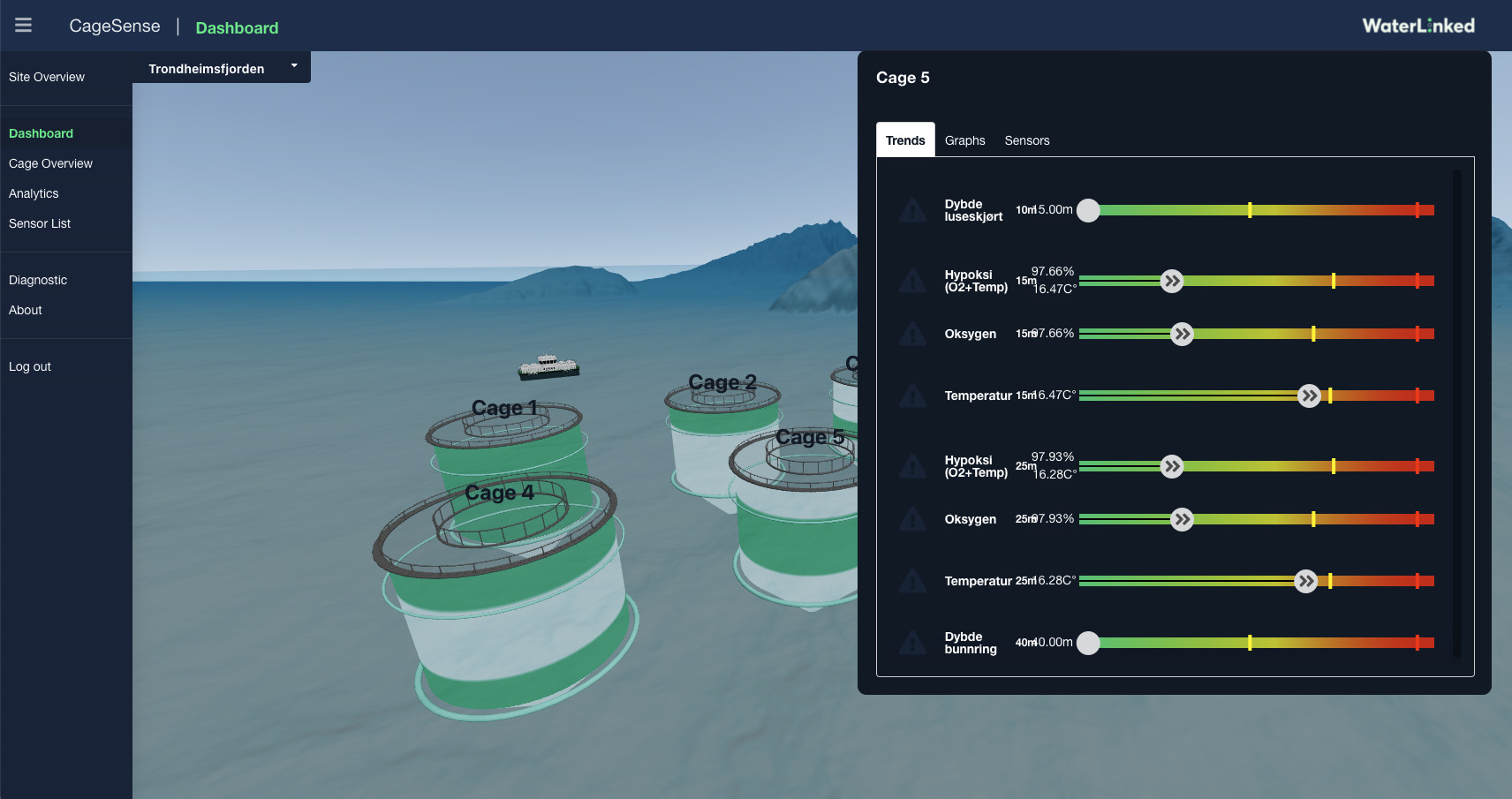

– Our sensors measure and transmit data through a topside unit to a cloud storage platform or local storage onboard the barge. Transmitting and saving sensor data is something also other solutions can do, but what makes CageSense™ so unique is first of all that all data is transmitted completely wirelessly. Secondly, the data gets structured and output in an intuitive graphical user interface (GUI) that provides a convenient status overview of the farm, telling the operator which actions need to be taken, says Sirnes.

He further explains that a third benefit of CageSense™ is its open API. Through the system’s API, one can either import data from CageSense™ seamlessly into a third party dashboard, or one can use it the other way - to integrate third party solutions into the CageSense™ dashboard. This makes it convenient to integrate and adapt the product with existing solutions in use at various fish farms.

Wireless solution ensures safe operation

Sirnes is an experienced product and business developer in the aquaculture industry, also prior to his time at Water Linked. According to him, it was the need for a wireless monitoring solution that sparked the development of CageSense™ 18 months ago:

– A wireless solution protects you from breakage and leakage, making the operation both safer and more convenient. In addition, the environmental impact is reduced, and not to mention the fact that reducing the number of objects on the edge of the cage.

He adds that also installing the wireless sensors is a much less resource heavy task than with conventional systems relying on cables to be run. The same goes for when you want to change or expand your existing system.

Intuitive GUI provides an instant overview

Another aspect that made developing a new fish farm monitoring system attractive for Water Linked was the industry’s need for a more intuitive user interface. Once the system is up-and-running, you don’t need to be experienced with interpreting the data as it is presented in conventional solutions:

– CageSense™ doesn’t just overload you with figures and percentages for yourself to analyze. The calculations have already been made for you. Based on FHF’s welfare indicators for aquaculture, the system tells you whether the values are good, borderline or whether they do not meet requirements, Sirnes explains.

The status of each parameter is color coded using the colors green, yellow and red to provide an instant overview and it’s no coincidence that these are the same colors you recognize from traffic lights:

– Whether you are experienced with interpreting environmental fish farm data or you are fresh in the field, you will likely be able to respond quicker to a status color changing from green to red than you would to a numerical value changing.

Sirnes further elaborates that CageSense™ reports all irregularities in real-time. Now the operator knows not only what is wrong and how to fix it, but they will know it as soon as it occurs. This makes the operator much better suited to mitigate the possible impact of the irregularity. The real-time data will also display tendencies in the data provided. This means that the operator can choose to receive a pre-warning before a parameter enters the “red zone”.

International interest

CageSense™ has already been sold to two fish farmers in Central Norway, Sirnes explains, and the demand for the product has been good - with several international companies having been in touch. Launching CageSense™ domestically to begin with was a conscious choice, according to Sirnes.

– First of all we want to gain experience and continue developing CageSense™ in collaboration with forward-leaning fish farmers with a sustainable and long-term perspective on production and fish welfare. Since Norway is a pioneering nation when it comes to aquaculture, many fish farms that fit the bill exist and thrive here.

– Secondly, we are aware that the international market might not be fully mature for this yet. Many international fish farms are still in other maturation stages of the industry when it comes to utilizing new technology. There are of course many honest exceptions to this rule, and we have no doubt that more and more international aquaculture businesses will adapt new technology that allows them to run a more sustainable and productive operation built for the future. At that time we will be ready for them, Sirnes concludes.